- Home Page

- Company Profile

-

Our Products

- Sweet Making Machinery

- Beshan Laddu Making Machine

- Automatic Penda Making Machine

- Automatic Gulab Jamun Making Machine

- Khoya Making Machine

- Peda Machine

- Multipurpose Rounder Machine

- Halwa Machine

- Gulab Jamun Frying Machine

- Roasting machine

- chikki Making Machine

- Sweets Making Machinery

- Rasgulla Making Machine

- Automatic Rasgulla Making Machine

- 30" 6BS MAWA MACHINE

- Laddu Making Machine

- Cham Cham Making Machine

- kaju musti machine

- Lathe Machine

- Namkeen machine

- Vegetable Cutting Machine

- Potato Peeler Machine

- Banana Slicer Machine

- Barfi cutting Machine

- Sweet Making Machinery

- Contact Us

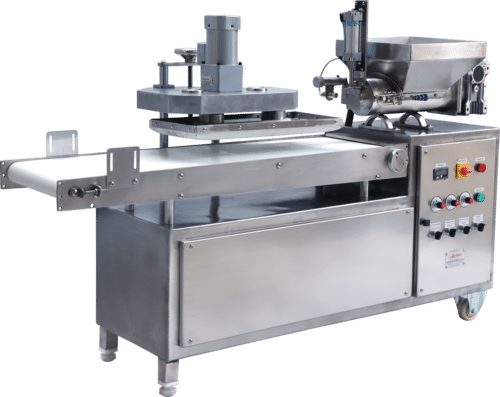

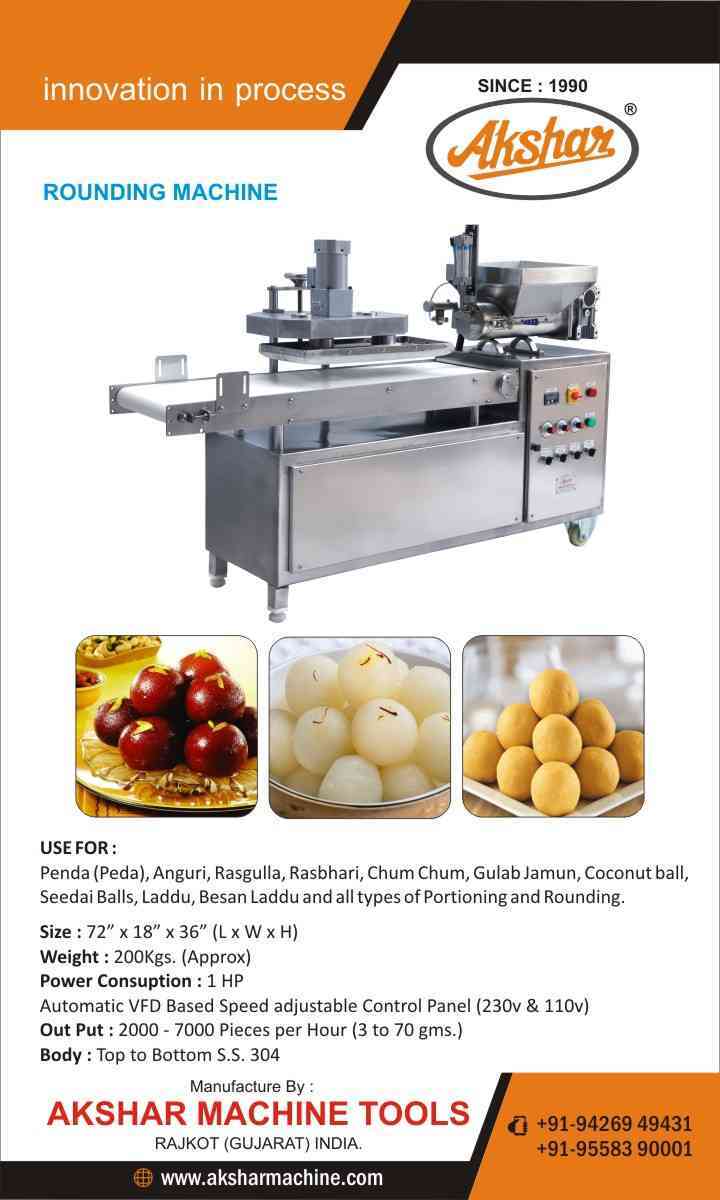

Rasgulla Making Machine

300000.00 INR/Piece

Product Details:

- Heating Method External (not included)

- Feeding System Continuous

- Machine Type Food Processing

- Operating Temperature Ambient to 80C Celsius (oC)

- Automation Grade Automatic

- Function Type Forming, Cutting and Dispensing

- Speed Mode Variable

- Click to view more

X

Rasgulla Making Machine Price And Quantity

- 300000.00 INR/Piece

- 1 Piece

Rasgulla Making Machine Product Specifications

- Round (Rasgulla Balls)

- Low Maintenance, User Friendly Interface

- Rasgulla Making Machine

- 1000-12000 pcs/hr Pcs/hr

- Variable

- White

- Stainless Steel

- Forming, Cutting and Dispensing

- Yes

- PLC Control

- Automatic

- 220-240 Volt (v)

- 50/60 Hz Hertz (HZ)

- Ambient to 80C Celsius (oC)

- Food Processing

- Yes

- Single or Three Phase

- Industrial Sweet Manufacturing

- External (not included)

- Continuous

- Machine

- Electric

- 1040 x 900 x 1150 mm Millimeter (mm)

Rasgulla Making Machine Trade Information

- 10 Piece Per Month

- 1 Months

- All India

Product Description

A rasgulla making machine is a specialized piece of equipment used in the production of rasgulla, a popular Indian dessert made from chhena (an Indian cottage cheese) and sugar syrup. This machine automates the process of forming and shaping the chhena mixture into uniform round balls, which are then cooked in sugar syrup. It typically consists of a conveyor belt system or molds to shape the rasgulla dough, ensuring consistency in size and shape. Rasgulla making machines are commonly used in commercial kitchens, sweet shops, and food processing facilities to increase efficiency and productivity in rasgulla production.

Consistent and High-Quality Output

This machine manufactures perfectly round rasgulla balls with uniform size and texture. The PLC-controlled system ensures efficiency, productivity, and repeatability for every batch, which is critical for meeting market quality expectations. Output can be customized to your production demands, ranging from 1,000 to 12,000 pieces per hour.

Safety and Compliance First

Operator wellbeing is ensured through built-in safety features, including an emergency stop button and overload protection. The product is fully compliant with FSSAI food safety regulations, making it suitable for commercial operations across India. Mirror-polished stainless steel construction promotes hygiene in food processing.

Effortless Operation and Maintenance

Designed for ease of use, the machine operates with a user-friendly interface and can be handled by a single operator. Its detachable parts and included cleaning system make daily maintenance straightforward. Accessories such as nozzle sets and a user manual further support efficient operation.

FAQs of Rasgulla Making Machine:

Q: How does the Rasgulla Making Machine ensure uniform size and shape?

A: The machine uses advanced PLC control systems and precision nozzles to form and dispense rasgulla balls of consistent size and round shape. This automation guarantees each batch maintains strict uniformity, enhancing product quality and appearance.Q: What safety features are incorporated in this machine?

A: Safety is prioritized through features like an emergency stop button and overload protection. These mechanisms allow operators to respond quickly to any unforeseen error and protect both personnel and equipment during operation.Q: When is this machine ideal for use?

A: This Rasgulla Making Machine is ideal for mid-to-large-scale sweet makers seeking high efficiency and uniform product quality. It is particularly beneficial during periods of high demand or for businesses aiming to scale production while maintaining FSSAI compliance.Q: Where can the Rasgulla Making Machine be installed?

A: With its free-standing design and moderate footprint (1040 x 900 x 1150 mm), the machine fits easily into industrial kitchens, sweet manufacturing facilities, or commercial food processing units across India.Q: What is the process of cleaning and maintaining the machine?

A: Daily cleaning is simplified due to detachable machine parts and an integrated cleaning system. Regular maintenance involves basic sanitation and inspection, promoting longevity and hygienic operation.Q: How is the machine operated, and what manpower is required?

A: Operation is fully automatic and managed via a user-friendly PLC interface, requiring only one operator. The included manual and accessories support both beginner and experienced users.Q: What are the key benefits of using this machine for rasgulla production?

A: Key benefits include high output capacity, labor reduction, consistent product quality, compliance with food safety standards, low maintenance needs, and adaptability for a range of input sizes and production scales.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email